Duplex asye pur refere a yon materyèl ki gen mikrostruktur ki konpoze de ferit ak austenit, chak kontablite pou apeprè 50%. Nan itilizasyon aktyèl, li pi apwopriye pou youn nan faz yo ant 40-60%.

Dapre karakteristik sa yo nan estrikti a de-faz, pa byen kontwole konpozisyon chimik la ak pwosesis tretman chalè, severite a ekselan ak weldability nan asye austenitik Nerjaveèi yo konbine avèk fòs la pi wo ak klori estrès rezistans kowozyon Pwopriyete fizik yo se ant asye pur austenitik ak asye pur feritik, men pi pre asye pur feritik ak asye kabòn. Rezistans nan klori opoze ak fant korozyon nan duplex asye pur ki gen rapò ak kontni an nan CHROMIUM, MOLYBDENUM ak nitwojèn. Rezistans li nan opozisyon ak fant korozyon ka menm jan ak sa yo ki an 316 asye pur, oswa pi wo pase sa yo ki an asye pur pou dlo lanmè, tankou 6%mo austenitik asye pur. Tout asye pur duplex yo siyifikativman plis rezistan a klori estrès korozyon cracking pase 300 seri asye pur austenitik, ak fòs yo se tou pi wo pase asye austenitik Nerjaveèi, pandan y ap montre bon plastisit ak severite.

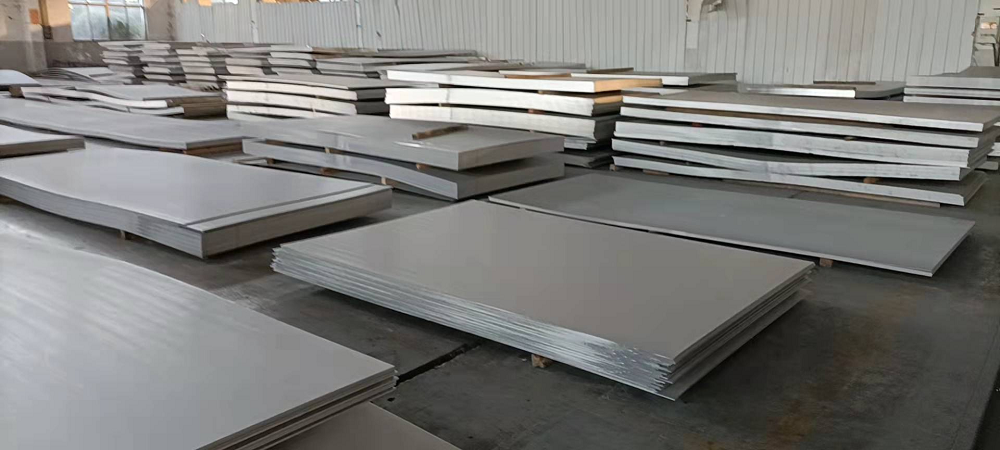

Divès kalite fòm pwodwi nan Duplex asye pur: plak ak bann tiyo -tiyo welded ak tiyo san pwoblèm forgings tiyo ekipman ak baton baton ak fil

Duplex asye pur ka jeneralman divize an kat kategori:

Youn: Kalite alyaj ki ba, Reprezantan Klas UNSS32304, Steel pa gen Molibden, Pren: 24-25, ka ranplase AISI 304 oswa 316 an tèm de rezistans korozyon estrès.

De: Mwayen Kalite Alloy, Reprezantan Klas UNSS31803, PREN: 32-33, rezistans korozyon se ant AISI316L ak 6%Mo+N Austenitik asye pur.

Twa: kalite alyaj segondè, jeneralman ki gen 25% CR, tou gen molibdèn ak nitwojèn, kèk tou gen ladan kòb kwiv mete ak tengstèn, klas estanda yo se UNSS32550, pren: 38-39, rezistans korozyon se pi wo pase 22% cr duplex asye pur.

Kat: Super duplex kalite asye pur, ki gen segondè molibdèn ak nitwojèn, klas estanda yo se UNSS32750, kèk tou gen ladan tengstèn ak kwiv, Pren> 40, yo ka itilize nan kondisyon mwayen piman bouk, ak bon rezistans korozyon ak pwopriyete mekanik konplè, konparab ak super austenitic asye. (Remak: Pren: rezistans rezistans valè ekivalan)

Konpozisyon Chimik eleman yo alyaj prensipal nan asye duplex yo Cr, Ni, Mo ak N. Pami yo, Cr ak Mo yo te itilize ogmante kontni an ferit, pandan y ap Ni ak N yo se eleman estabilize austenit. Gen kèk klas asye tou gen eleman tankou Mn, Cu, ak W. Cr, Ni, ak Mo ka amelyore rezistans korozyon. Rezistans li nan opozisyon ak kreyòl nan fant se patikilyèman bon nan klori ki gen anviwònman.

Avantaj nan duplex asye pur

1. Konpare ak asye pur austenitik

1) fòs la sede se plis pase doub sa yo ki an òdinè asye pur austenitik, epi li gen ase plastisit ak severite ki nesesè pou fòme. Epesè nan tank depo oswa veso presyon te fè nan duplex asye pur se 30-50% mwens pase sa yo ki an souvan itilize asye pur austenitik, ki se fezab diminye depans yo.

2) Li gen ekselan rezistans nan estrès korozyon fann, espesyalman nan anviwònman ki gen iyon klori. Menm duplex asye pur ak kontni an alyaj ki pi ba gen pi wo rezistans nan estrès korozyon fann pase austenitik asye pur. Kowozyon estrès se yon pwoblèm enpòtan ki òdinè asye pur austenitik se difisil yo rezoud. 3) rezistans nan korozyon nan pi komen 2205 duplex asye pur yo itilize nan anpil medya se pi bon pase sa yo ki an òdinè 316L asye pur austenitik, ak super duplex asye pur gen ekstrèmman wo rezistans korozyon. Nan kèk medya, tankou asid acetic ak asid fòmik, li ka menm ranplase wo-alyaj austenitik asye pur ak menm alyaj korozyon ki reziste. 4) Li gen bon rezistans lokal korozyon. Konpare ak asye pur austenitik ak kontni an menm alyaj, rezistans mete korozyon li yo ak rezistans fatig korozyon yo pi bon pase asye pur austenitik. 5) koyefisyan ekspansyon lineyè a pi ba pase sa ki nan asye pur austenitik, fèmen nan sa yo ki an asye kabòn, apwopriye pou koneksyon ak asye kabòn, e li gen enpòtans jeni enpòtan, tankou pwodiksyon an nan plak konpoze oswa garnisaj.

2. Konpare ak asye pur feritik, avantaj ki genyen nan duplex asye pur yo jan sa a:

1) pwopriyete yo konplè mekanik yo pi wo pase sa yo ki nan asye ferritik pur, espesyalman severite plastik. Li se pa tankou sansib a fragilite kòm feritik asye pur.

2) Eksepte pou rezistans korozyon estrès, lòt rezistans lokal korozyon se pi bon pase feritik asye pur.

3) Pèfòmans pwosesis frèt ak pèfòmans frèt fòme yo pi bon pase ferritic asye pur.

4) Pèfòmans nan soude se pi bon pase ferritic asye pur. Anjeneral, pa gen okenn prechofe obligatwa anvan soude epi yo pa gen okenn tretman chalè ki nesesè apre soude.

5) Range aplikasyon an se pi laj pase sa yo ki an feritik asye pur.

Aplikasyon

Akòz gwo fòs asye duplex, li ka souvan sove materyèl yo, tankou diminye epesè miray tiyo a. Pran SAF2205 ak SAF2507W kòm egzanp. SAF2205 se apwopriye pou itilize nan anviwònman klò ki gen. Materyèl sa a apwopriye pou raffinage lwil oswa lòt medya pwosesis melanje ak klorid. SAF2205 se patikilyèman apwopriye pou echanjeur chalè ki sèvi ak klò ki gen solisyon akeuz oswa yon ti kras sale dlo kòm medya refwadisman. Materyèl sa a tou se apwopriye pou solisyon dilye asid silfirik ak pi bon kalite asid òganik ak melanj yo. Pou egzanp: tiyo lwil oliv nan endistri a lwil oliv ak gaz: desalman lwil brit nan raffineries, souf ki gen pirifye gaz, ekipman tretman dlo ize; Sistèm refwadisman lè l sèvi avèk yon ti kras dlo sale oswa klò ki gen solisyon yo.

Post tan: Feb-05-2025